Our Story

When RDM Industrial Electronics' Doug Long says, "It's very much a family environment here," it isn't just a cliché. "Throughout the years, we've had our wives, children, mother, aunts, uncles and local church members work here," he says with a chuckle.

That family atmosphere was ingrained from the company's start in February 1988, when brothers Rick, Doug and Mike Long, each of whom earned a degree in electronics, formed the company in Mike's basement, rebuilding electronic boards, printers and tank monitors made by other equipment manufacturers.

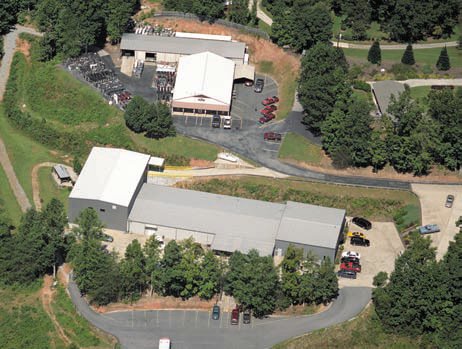

Within a year, the company moved out of the basement—"When you start in the basement,

up is the only way to go," Rick says'into a 4,000 sq. ft. facility. Three building projects

and two decades later, the company now fills to capacity a 30,000 sq. ft. facility in western North Carolina.

Four years ago, RDM acquired a competitor in Denver, Colorado,

and added car wash electronics to its repertoire.

Within a year, the company moved out of the basement—"When you start in the basement,

up is the only way to go," Rick says'into a 4,000 sq. ft. facility. Three building projects

and two decades later, the company now fills to capacity a 30,000 sq. ft. facility in western North Carolina.

Four years ago, RDM acquired a competitor in Denver, Colorado,

and added car wash electronics to its repertoire.

After Mike, the youngest brother, passed away seven years ago, Rick and Doug kept the momentum going. The two brothers serve as copresidents, Rick overseeing sales and marketing activities and Doug overseeing operations. The remainder of the management team includes Richard Mull, electronics division manager; Rick White, mechanical division manager; and David Gallion, sales manager. "Our sales have grown every year we've been in business," Rick says, adding that RDM's revenues have doubled since 2001.

RDM boasts the largest stock of remanufactured equipment in the industry. "We have the products that any distributor would need. The availability of products that we have blows our competition away," Rick says. "We're not the oldest in the industry, but we're the most reliable."

The RDM Advantage

RDM cites numerous other advantages over OEMs and other rebuilders as reasons for its remanufacturing success. Principal among those are speed, price and experience. RDM's large finished goods stock makes its shipping times much faster than the original manufacturer can provide in most cases. "We are open until 7:00 p.m. Eastern time, and with our additional Denver facility, we can ship an order the same day to distributors anywhere in the country," Rick says. "Every order that can go out that day will be shipped, which means a lot to customers who depend on us to stock products that they don't have to stock themselves." The remanufactured equip-ment is also a lower-cost alternative to new products. Such strategy takes pressure off distributor purchasing managers, who know they can call RDM for virtually any product they need without delay.

RDM also boasts a staff with unrivaled industry experience. "Most of our technicians have between

10-20 years of experience working on a particular piece of equipment," Doug points out. "In a lot

of cases, we have more experience than the manufacturers."

RDM also boasts a staff with unrivaled industry experience. "Most of our technicians have between

10-20 years of experience working on a particular piece of equipment," Doug points out. "In a lot

of cases, we have more experience than the manufacturers."

A very low turnover rate is another way the company's family atmosphere manifests itself. Doug adds, "We have some technicians who have been here almost the entire time we've been in business."

RDM works with local community colleges to develop curriculum and recruit "the cream of the crop," according to Doug. "We're very selective on who we hire. We want excellent character as well as good grades." Once with the company, RDM employees receive very competitive wages and benefits, including 100 percent tuition reimbursement for advanced degrees. "We want our employees to continue their training and allow us to stay state-of-the-art when many other companies cannot," says Doug. This level of training allows RDM to supply other rebuilders with some of the more complex board work, including surface-mount technology.

Because of that unparalleled level of expertise, RDM is able to remanufacture products using reverse engineering techniques and a highly integrated schematic simulation software. "Our technicians are able to fabricate full schematic designs very quickly by analyzing the electronic boards," Doug explains.

When a manufacturer releases a new product to the marketplace, often RDM will buy it in order to learn how it is built. "We'll be up to speed on that piece of equipment before it even comes out of warranty," Doug says. "We intend to be the first in the marketplace on any piece of new equipment." Within a year or two, when the orders start coming in for that particular piece of remanufactured equipment, RDM already has it in stock and ready to deliver to customers.

Top-Notch Customer Service

RDM's 73 employees are dedicated to providing the industry's best customer service. The inside sales team is comprised of seven highly qualified individuals, including a salesperson fluent in Spanish. Outside the company, physically closer to RDM's customers, is a team of manufacturers representatives. Their time is spent traveling across their respective territories across North America, calling on distributors.

"We want a personal relationship with all of our customers," Rick says. The best way to do that is to

be around them at regional trade shows. With the addition of two tradeshows in Canada, Rick, Doug and

Sales Manager David Gallion attend about 18 per year. This includes the PEI show at NACS, the company's

biggest event of the year. "The exposure we've gotten from PEI has helped us nationally and

internationally," Rick says. About seven percent of RDM's business is conducted outside the United States.

"We want a personal relationship with all of our customers," Rick says. The best way to do that is to

be around them at regional trade shows. With the addition of two tradeshows in Canada, Rick, Doug and

Sales Manager David Gallion attend about 18 per year. This includes the PEI show at NACS, the company's

biggest event of the year. "The exposure we've gotten from PEI has helped us nationally and

internationally," Rick says. About seven percent of RDM's business is conducted outside the United States.

International business is helped by RDM's aggressive Internet presence. What was once strictly an informational site has been revamped in 2008 to include more customer-friendly options. Users will find a comprehensive list of rebuilt equipment that RDM has in stock, along with a list of cores RDM is aggressively seeking. The site is now also home to an e-store available to distributors only. "Distributors can place orders—which would of course be shipped that day—and soon will be able to pull up their statement and see where they stand with us," Rick explains. "It was a little bit of a challenge to develop, but we want our distributors—not just anybody—to be able to buy off our Web site. We don't sell direct to end-users." That ease of use is critical to RDM, and the philosophy also extends to telephone tech support Distributors can call into RDM's toll-free number for assistance and troubleshooting. "The easier we are to use, the more they'll buy from us," says Doug.

Such forays into technology help give RDM a firm grip on its future, which Rick sees as more of the same successes. "I see continued growth. We keep expanding our customer base, expanding our product offerings. We continually look to diversify within our industry as well as outside of the petroleum industry," says Rick.

"We have experience in enough advanced technology from this industry that there really are no upper limitations on what our company can become," Doug adds.

This advertorial originally appeared in the First Quarter, 2008 issue of The PEI Journal Copyright ©Data Key Communications, Inc. All rights reserved.